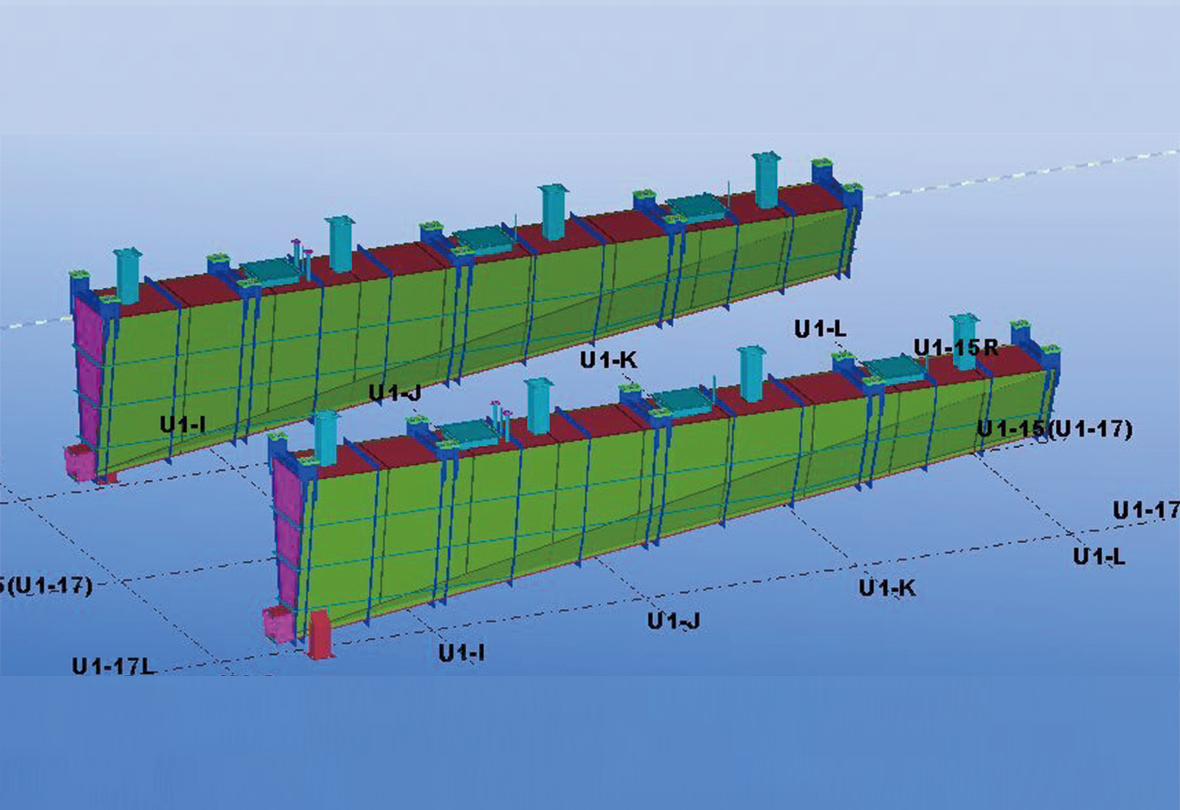

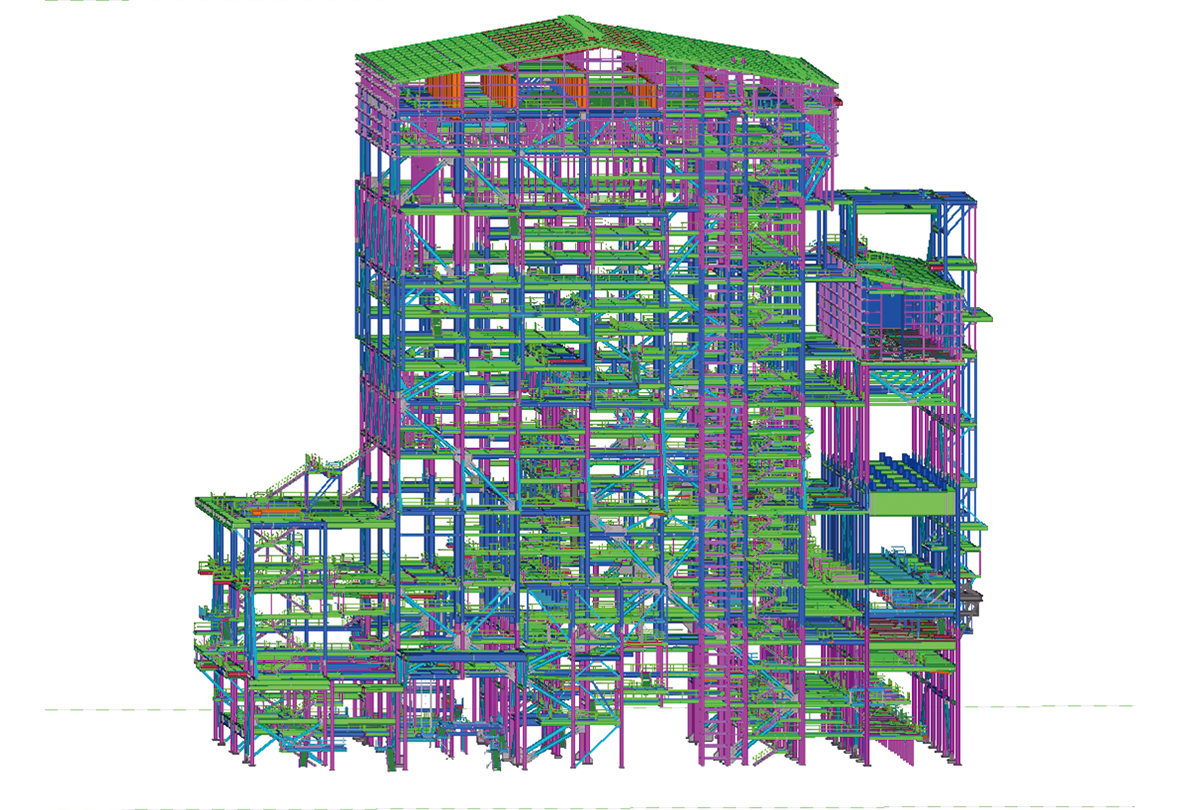

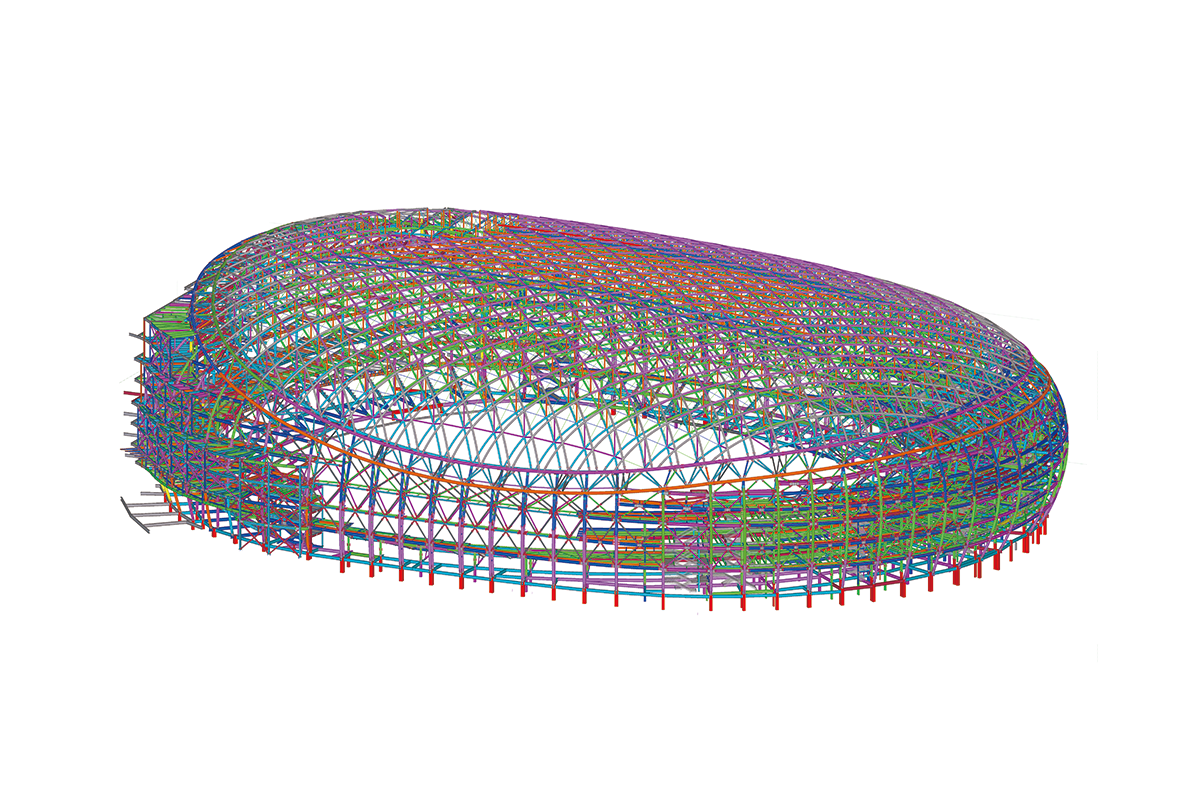

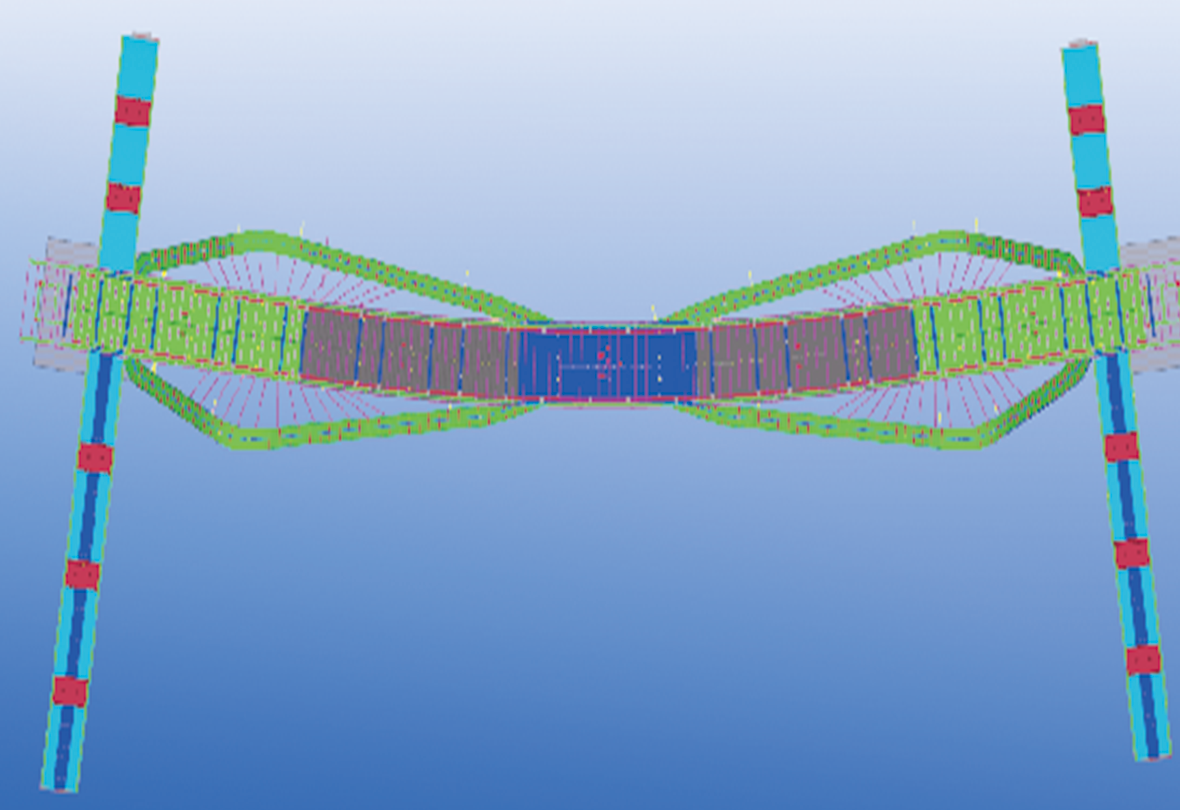

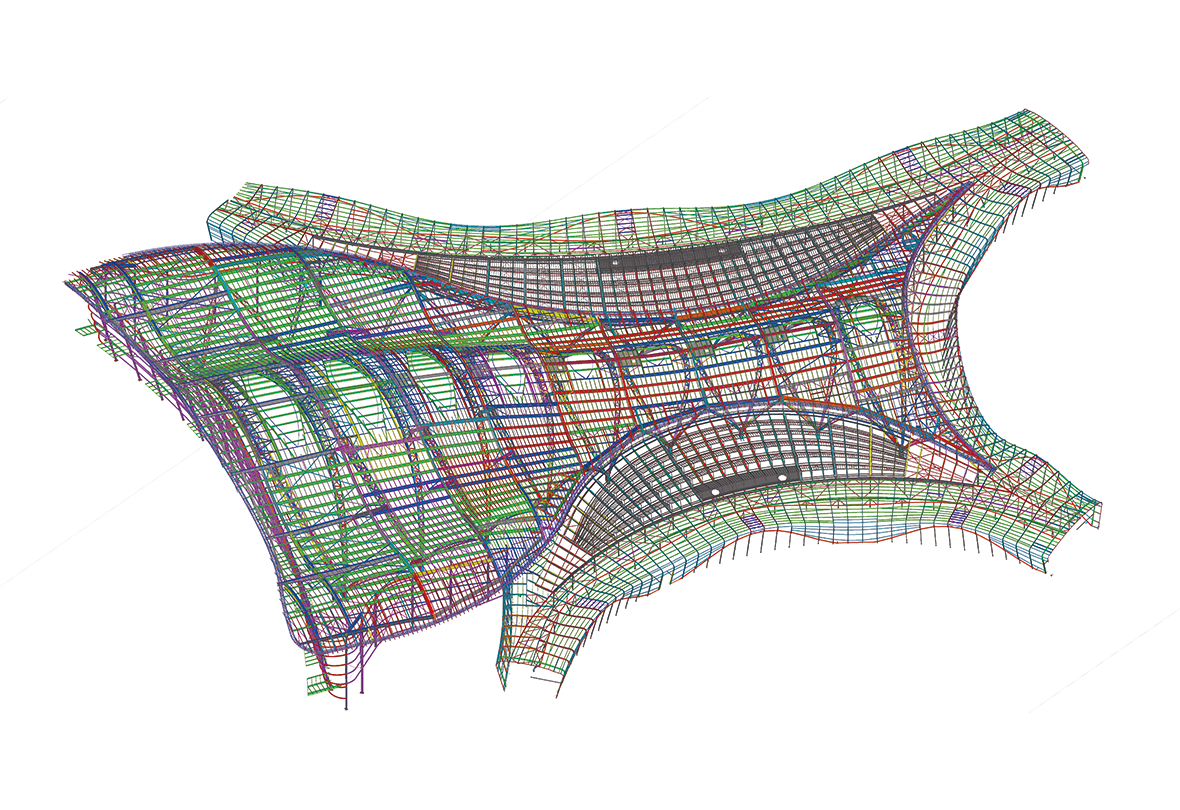

作品介绍

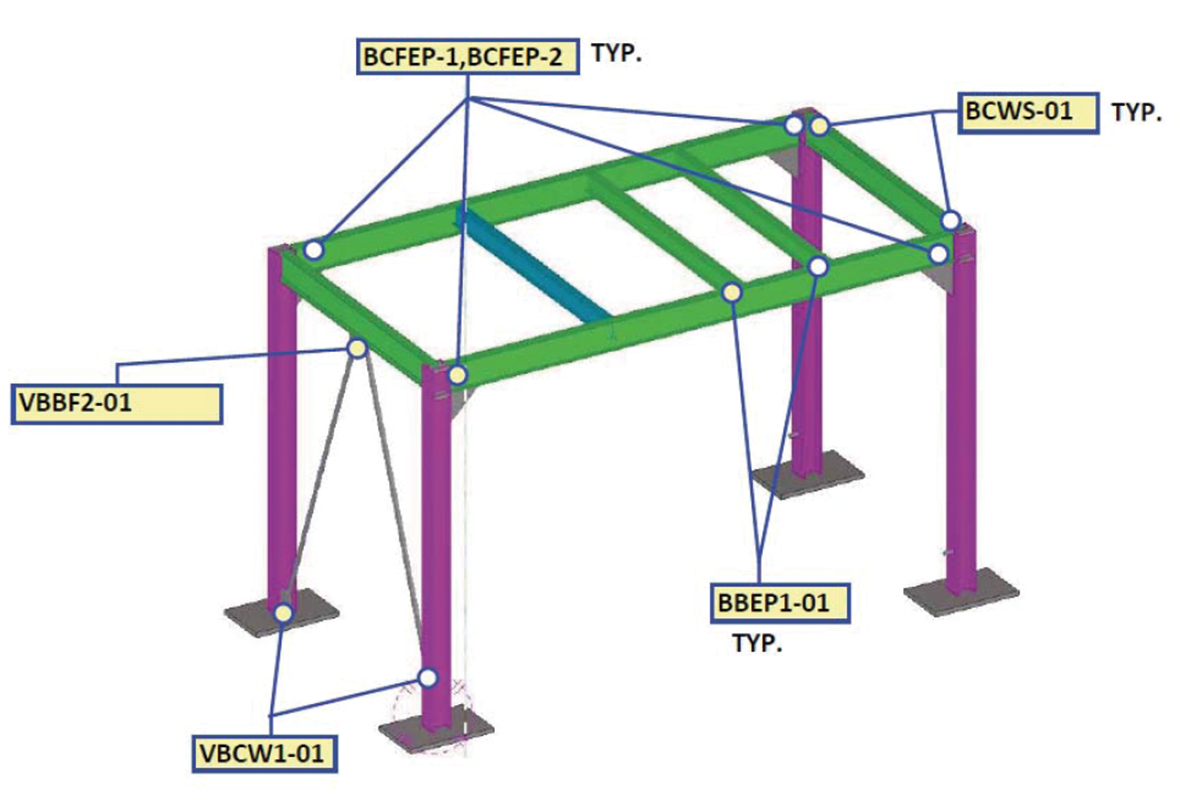

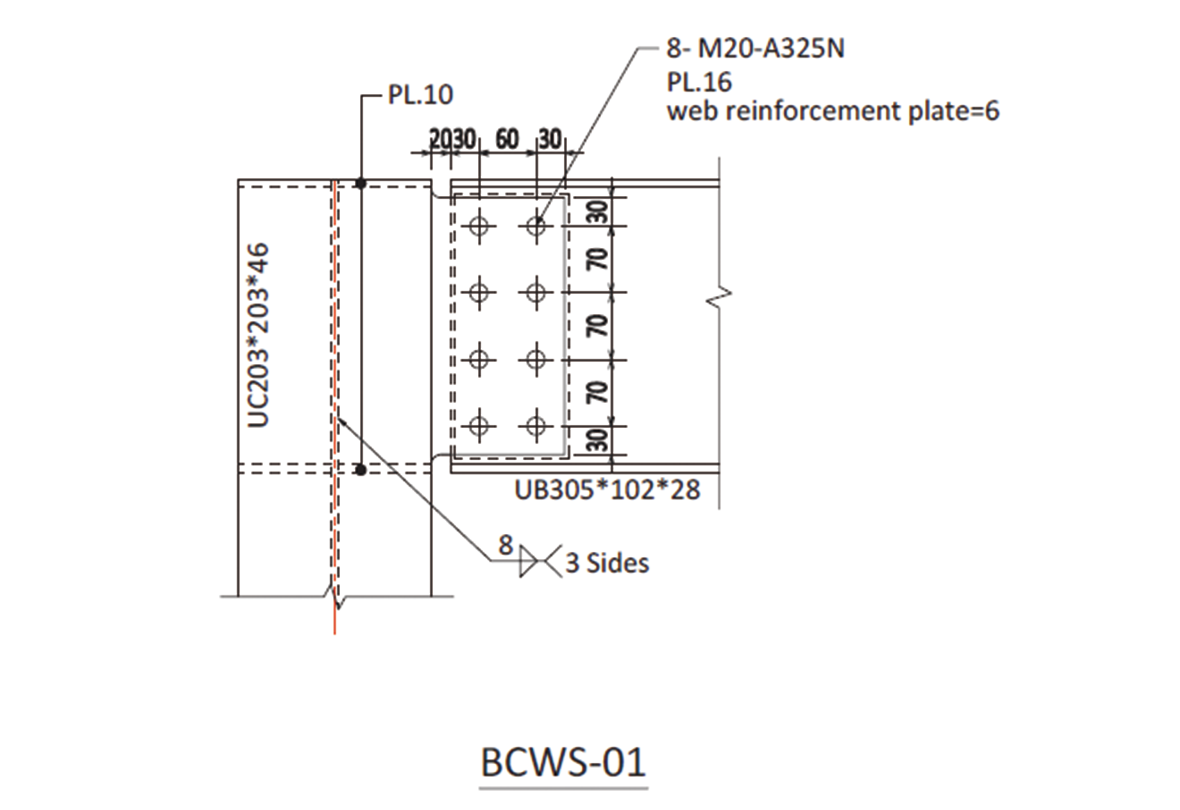

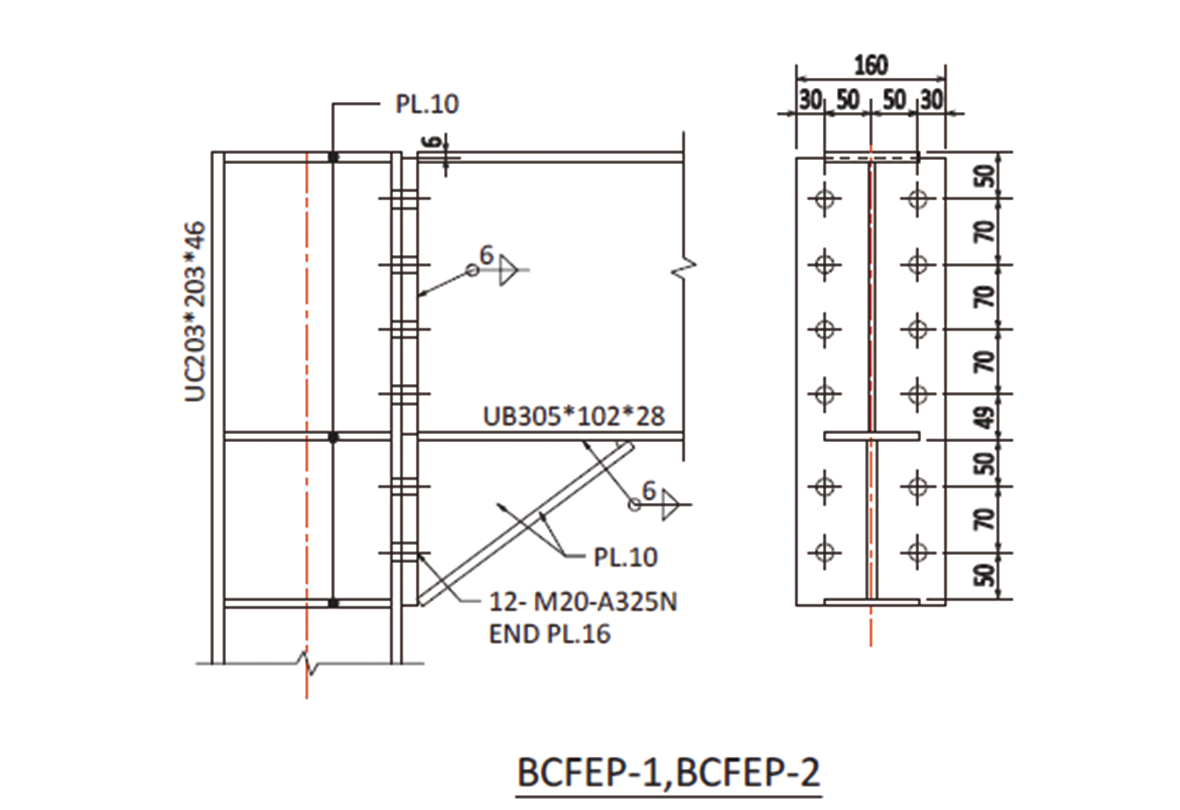

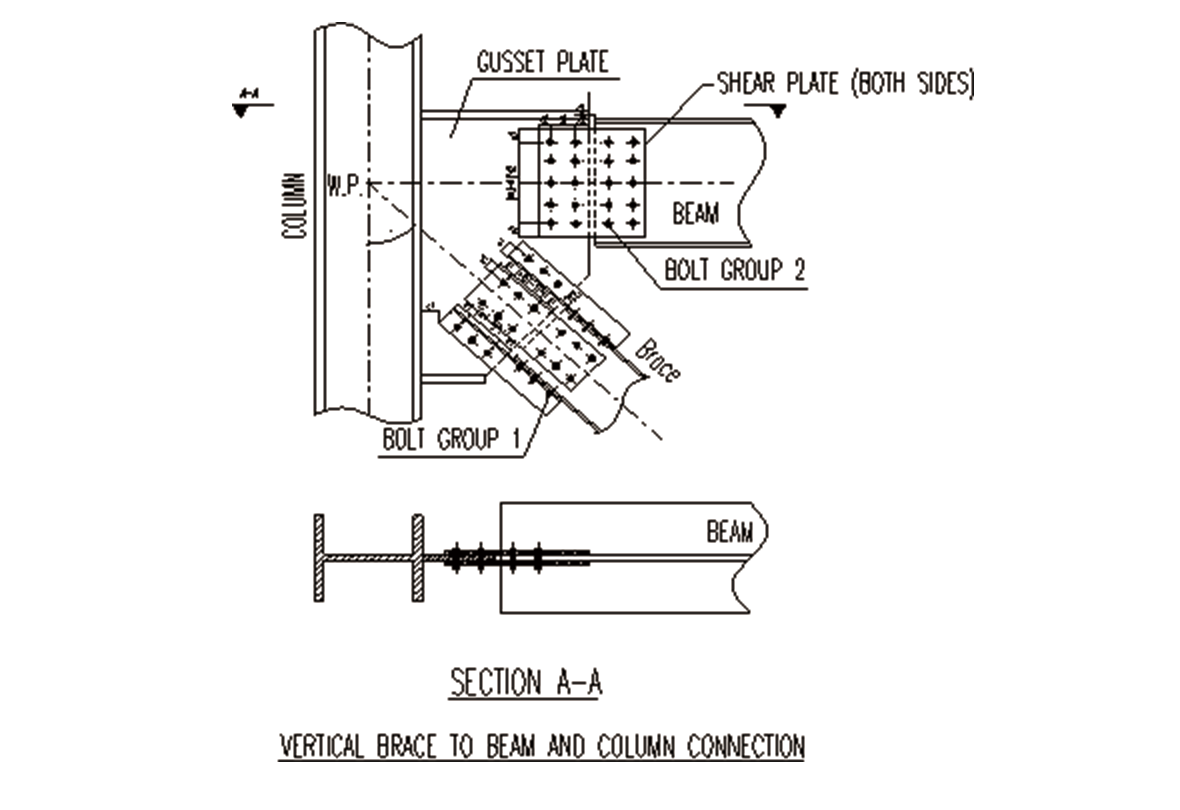

钢结构节点设计是钢结构工程中的关键环节。它主要负责确定各钢构件之间的连接方式与细节构造,以确保整个结构的稳定性、承载能力和可靠性。

在设计过程中,需综合考虑多种因素。首先是力学性能,依据结构所承受的荷载大小、方向及作用点,精确计算节点处的受力情况,从而选择合适的连接形式,如焊接、螺栓连接或铆接等,并确定连接件的规格尺寸,保证节点能有效传递内力。同时,要考虑施工的可行性与便利性,确保节点构造便于现场安装操作,提高施工效率与质量。此外,还需关注节点的耐久性,采取相应的防腐、防火等措施,以适应不同的使用环境。通过精心的钢结构节点设计,使各钢构件紧密相连,协同工作,为钢结构建筑或设施的安全与稳定奠定坚实基础,在工业厂房、高层建筑、桥梁等众多领域发挥着重要作用。

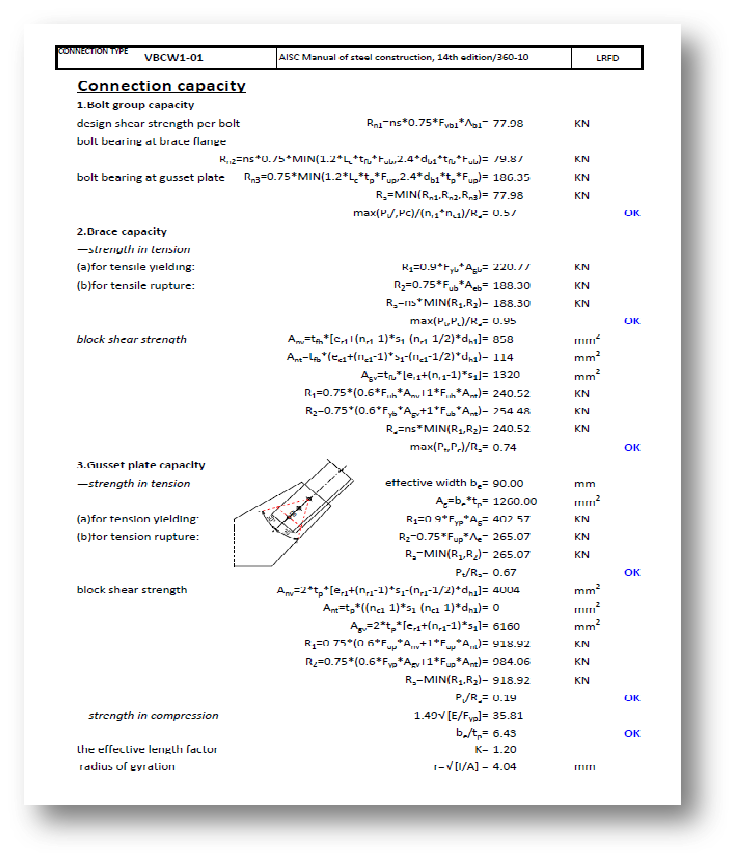

计算表

|

CONNECTION TYPE |

VBC2-02_01 |

AISC Manual of steel construction, 9th edition |

REV.0 |

||||

|

|

Connection capacity |

|

|

|

|

||

|

|

1.Bolts group capacity |

|

|

|

|

||

|

|

(1)at brace flange |

|

|

|

|

|

|

|

|

—allowable slip resistance |

|

|

|

|

||

|

|

|

|

Fa1= |

Fv1*Av1 |

|

|

|

|

|

|

|

= |

113.81 |

KN |

|

|

|

|

—bolt bearing at flange of brace |

|

|

|

|

||

|

|

|

|

Fa2= |

1.2*Fub*Ab |

|

|

|

|

|

|

|

= |

184.41 |

KN |

|

|

|

|

—bolt bearing at gusset plate |

|

|

|

|

||

|

|

|

|

Fa3= |

1.2*Fugp*Ab |

|

|

|

|

|

|

|

= |

483.49 |

KN |

|

|

|

|

—bolt bearing at angle |

|

|

|

|

||

|

|

|

|

Fa4= |

1.2*Fua*Ab |

|

|

|

|

|

|

|

= |

154.31 |

KN |

|

|

|

|

|

|

Fa=MIN(Fa1,Fa2,Fa3,Fa4)= |

113.81 |

KN |

|

|

|

|

|

|

[Ptf/(nr1*nc1)]/Fa= |

0.00 |

|

OK |

|

|

|

|

|

[Pcf/(nr1*nc1)]/Fa= |

0.30 |

|

OK |

|

|

|

|

|

|

|

|

|

|

|

|

(2)at brace web |

|

|

|

|

|

|

|

|

—allowable slip resistance |

|

|

|

|

||

|

|

|

|

Fa1= |

Fv1*Avb1 |

|

|

|

|

|

|

|

= |

227.63 |

KN |

|

|

|

|

—bolt bearing at web of brace |

|

|

|

|

||

|

|

|

|

Fa2= |

1.2*Fub*Ab |

|

|

|

|

|

|

|

= |

184.41 |

KN |

|

|

|

|

—bolt bearing at gusset plate |

|

|

|

|

||

|

|

|

|

Fa3= |

1.2*Fugp*Ab |

|

|

|

|

|

|

|

= |

483.49 |

KN |

|

|

|

|

—bolt bearing at shear plate 1 |

|

|

|

|

||

|

|

|

|

Fa4= |

1.2*Fusp1*Ab |

|

|

|

|

|

|

|

= |

386.79 |

KN |

|

|

|

|

|

|

Fa=MIN(Fa1,Fa2,Fa3,Fa4)= |

184.41 |

KN |

|

|

|

|

|

|

[Ptw/(nrb1*ncb1)]/Fa= |

0.00 |

|

OK |

|

|

|

|

|

[Pcw/(nrb1*ncb1)]/Fa= |

0.26 |

|

OK |

|

|

|

|

|

|

|

|

|

|

相关主营业务

RELATED PRODUCT CENTER

Norgener FGD and Fabric Filter

Cameron LNG Liquefaction Project